Validating KPIs for the Supply Chain Network Visibility app

Use the Supply Chain Network Visibility app’s Inventory Classification Validation, Inventory Projection Validation, Value Assessment, and Network Validation views to validate the KPIs (key performance indicators).Then make any further adjustments you need directly in the Knowledge Model, to change the business logic to suit your requirements.

Start by working through the four Validation and Value Assessment views in their numbered order. The third view (Value Assessment) depends on the KPIs you’ll validate in the first and second views. The fourth view (Network Validation) doesn’t depend on the others. The table at the end of the topic lists the KPIs you’ll be validating, as they appear in the Knowledge Model.

Inventory Classification Validation

Review the inventory classification distribution across all materials and plants. Understand the relevance of the Excess Inventory Rate step by step. Trace the factors that play into the inventory classification on the material-plant level for each classification category.

Deep dive into material-plant combinations that couldn’t be classified with the conditions defined. Focus on the material-plant combinations with the biggest amount of valuated stock, which offer additional potential to identify value.

Inventory Projection Validation

Review open supply (inventory on hand, planned orders, purchase requisitions, purchase orders, production orders) and open demand (reservations, sales orders, independent requirements).

Review the resulting Inventory Projection, keeping in mind to filter on one material-plant combination to give consistent results in the chart and table.

Building on supply and demand orders, validate definitions for excess supply, excess open replenishment, uncovered demand, and uncovered demand for orders.

Value Assessment

Assess value opportunities and their respective building blocks for common inefficiencies:

Reduce obsolete stock

Deplete legacy stock

Prevent excess replenishment orders

Mitigate consumption orders at risk

Network Validation

Objects & Links Tab: Understand objects (nodes) and links (edges) as the building blocks of the Master Data Network. Review the resulting network and drill down on the individual link types, namely Bill of Materials and Bill of Distribution links.

Stream Calculation Tab: Understand the behavior of the LINK_PATH operator for extracting streams from the network. Review start node, end node, and all node constraints and the resulting streams. Assess the size of demand (downstream) and supply (upstream) networks. The validation is structured into four successive steps:

1. Analyze Start and End Nodes: Understand the material-plant combinations that represent the start and end of the extracted streams by reviewing the respective classification conditions.

2. Analyze Resulting Streams: Review the streams that are extracted by traversing the material network from start to end. Assess the distribution of streams lengths.

3. Analyze Material-Plant Objects in Supply Streams: Understand the role of material-plant combinations in the resulting streams as nodes. Assess their respective position in the streams, and the frequency of their occurrence.

4. Analyze Demand and Supply Networks: Review the size of demand and supply networks for start and end material-plant combinations. These relate to the material-plant combinations listed in the upstream and downstream tabs in the Material Insights dashboard.

When you’ve worked through the four Validation and Value Assessment views, if you need to make any further adjustments, you can change the business logic directly in the KPIs in the Knowledge Model, to suit your requirements. The main Knowledge Model for the Supply Chain Network Visibility app is “Knowledge Model”. “Knowledge Model” points to the base Knowledge Model stored in the Celonis Marketplace, which you can’t update directly. Changes that you make to the PQL formulas, KPI names, or formatting in “Knowledge Model” override the base Knowledge Model.

Each KPI in a Knowledge Model contains a PQL (Process Query Language) formula. Some KPIs are reused inside other KPIs as nested formulas. When you adjust the business logic in a single formula, and save it, the change is simultaneously reflected in all the KPIs that reuse the formula.

You work with Knowledge Models in Studio, and any changes you make are applied when you publish a new version of the app. You’ll need Analyst permissions on Studio and the Knowledge Model to modify any of the KPIs and their calculations. If you need training, check out the training track “Build Knowledge Models and Views” on the Celonis Academy.

Here’s how to work directly with the KPIs in “Knowledge Model”:

In the Celonis navigation menu, select Studio.

Find the Supply Chain Network Visibility app in your Studio space navigation.

Expand the package’s structure using the arrow.

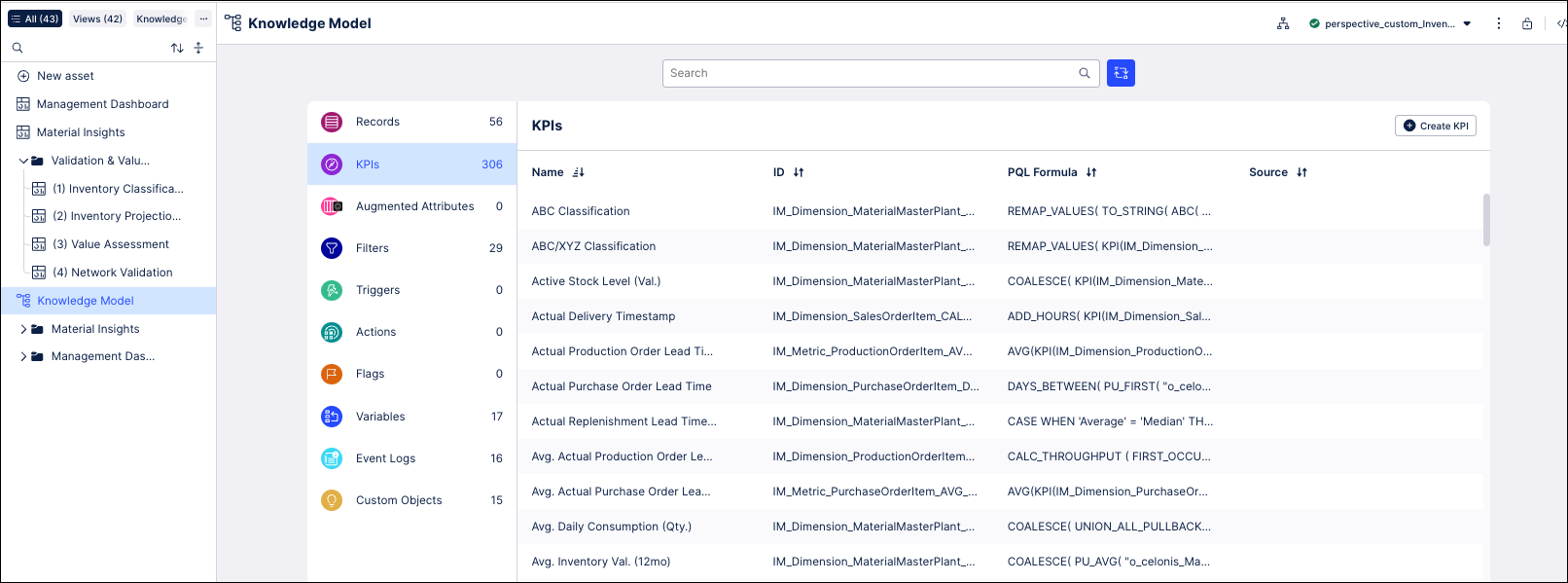

Go to the Knowledge Models folder and select “Knowledge Model”.

Select the KPIs section of the Knowledge Model.

You can sort and search the KPIs using their name or ID. The prefix to the ID shows what type of component they are. At the end of these instructions, we’ve listed the KPIs that you worked with in the Validation and Value Assessment views.

To see and edit the full PQL formula and other settings for a KPI, click its row to open an editor. The editor automatically validates any changes that you make in the PQL formula.

If you want a fuller-featured PQL editor that lets you select from the tables and columns in your data, click on the pen icon next to the PQL formula.

If you need to disable a KPI or formula, click the three vertical dots at the top of the editor, and select Disable Scope, then click Disable to confirm. When you do this, the object can't be accessed or used anywhere in the package, including by other apps that depend on it.

When you’ve made changes to the KPIs, use the Publish Package button at the top of the screen in your Studio space to publish a new version of the app.

Here are the KPIs that you validate in the Validation and Value Assessment views, as they appear in the Knowledge Model.

KPI ID | Formula description |

|---|---|

IM_Dimension_<ObjectName>_INDICATOR__IsOpen | Business logic that decides if a given order object is considered open. |

IM_Dimension_StockRequirementsList_UNIONALL__ProjectedInventoryQuantity | Running sum that computes supply against demand to obtain a projected future inventory level based on current confirmed and planned orders in your source system. |

IM_Dimension_MaterialMasterPlant_UNIONALLPULLBACK__DaysUntilStockOut | Number of days until the projected future inventory level will be below zero the next time. Situations where stock equals zero are not considered since there is no stock needed (yet). The KPI leverages all confirmed future consumptions and replenishments. |

IM_Dimension_MaterialMasterPlant_ADD__SupplyFutureQuantity | Business logic that defines open supply quantity. By default, this includes valuated inventory, planned orders, purchase requisitions, purchase orders, and production orders. |

IM_Dimension_MaterialMasterPlant_ADD__ConsumptionFutureQuantity | Business logic that defines open demand quantity. By default, this includes reservation orders, sales orders, and independent requirements. |

IM_Dimension_MaterialMasterPlant_CALC__TargetStockQuantity | Sums the initial stock level and the safety stock level to produce the target stock level. The target stock level is the threshold above which inventory is considered to be in excess. The initial stock level checks both the minimum lot size and the replenishment lead time multiplied by the consumption, and takes the larger result as the initial stock level. |

IM_Dimension_MaterialMasterPlant_CALC__ExcessSupplyQuantity | Remaining quantity after subtracting target stock or open demand (whichever is the greater number) from open supply. The result is the quantity not needed to satisfy existing demand or inventory targets. If there is uncovered demand for the same material-plant combination, excess will always be zero. |

IM_Dimension_MaterialMasterPlant_CALC__ExcessReplenishmentQuantity | Quantity from open replenishment orders that is not required to meet the open demand, based on target stock or open consumption (whichever is greater). |

IM_Dimension_MaterialMasterPlant_ABS__UncoveredDemandFutureQuantity | Remaining open demand quantity after all currently open supply has been consumed. If fulfilling open demand requires taking inventory out of safety stock, the quantity needed to refill this safety stock is considered uncovered demand as well. |

IM_Metric_MaterialMasterPlant_SUM__WorkingCapitalOpportunity | Sum of the total obsolete stock, legacy stock, and total excess stock values, plus the value of replenishment stock that isn't required to meet demand. |

IM_Dimension_MaterialMasterPlant_CALC__InventoryClassification | Classifies material-plant combinations into distinct categories. This categorization is mostly driven by the amount of inventory on hand, the target stock level, and the safety stock level. |

IM_Metric_MaterialMasterPlant_SUM_DemandOrderAtRisk | Remaining open demand value for orders after all currently open supply has been consumed. |

IM_Dimension_MaterialMasterPlantNetworkStream_PUSUM__DaysInInventory12Months | For a network stream, this is the sum of the days in inventory of all material-plant combinations in the stream. Days in inventory and days of cover are equivalent. |

IM_Dimension_MaterialMasterPlantNetworkStream_PUSUM__ReplenishmentLeadTime12Months | For a network stream, this is the sum of the replenishment lead time of all material-plant combinations in the stream. |

IM_Dimension_MaterialMasterPlantNetworkStream_PUSUM__ReplenishmentLeadTime12Months | For a network stream, this is the sum of the days in inventory and the replenishment lead time of all material-plant combinations in the stream. |